Introduction To

the Involvement of Electric Motors in Fuel Vehicles and Yuma's Demonstrated Advantages:

Fuel vehicles incorporate electric motors within auxiliary systems such as electric air conditioning compressors, electric power steering systems, and electric water pumps. Yuma's advantages lie in:

Customized Design Capability:

Yuma possesses a specialized team for tooling development and design, capable of crafting customized motor cores according to client specifications, catering to diverse auxiliary electric system needs.

Extensive Application Experience:

Yuma serves multiple sectors including industrial control, the new energy/automotive market, among others. Their products are extensively applied in automotive, robotics, household appliances, and other industries, showcasing diverse experience in motor system applications.

Customized Design Capability:

Yuma possesses a specialized team for tooling development and design, capable of crafting customized motor cores according to client specifications, catering to diverse auxiliary electric system needs.

Extensive Application Experience:

Yuma serves multiple sectors including industrial control, the new energy/automotive market, among others. Their products are extensively applied in automotive, robotics, household appliances, and other industries, showcasing diverse experience in motor system applications.

Fuel car

Fuel car Electrical machinery

Electrical machinery Car battery

Car battery

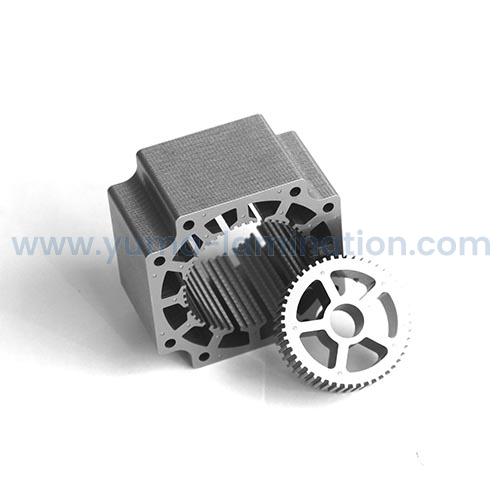

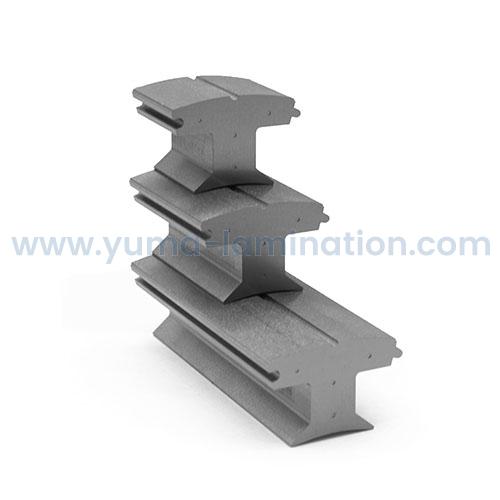

Yuma's Manufacturing Experience Evident in Fuel Vehicle Electric Motors

Yuma holds substantial manufacturing experience in various motor cores like stepper motors, servo motor cores, and automotive motor cores. In the electric auxiliary systems of fuel vehicles, their manufacturing expertise manifests in:

Precision Production: Owning large-scale manufacturing facilities equipped with advanced high-speed stamping presses, they achieve precise production of diverse motor cores, ensuring top-tier product quality.

Customization for Clients: Yuma has the capability to design and produce motor cores based on specific client needs, meeting specialized requirements for different auxiliary electric systems.

Precision Production: Owning large-scale manufacturing facilities equipped with advanced high-speed stamping presses, they achieve precise production of diverse motor cores, ensuring top-tier product quality.

Customization for Clients: Yuma has the capability to design and produce motor cores based on specific client needs, meeting specialized requirements for different auxiliary electric systems.

Manufacturing Capacity

The company possesses three R&D centers, namely product R&D, tooling R&D and equipment R&D, including more than 20% of R&D personnel and over 50 invention patents and utility model patents.The company has won the "Brand Building Award" for many times, "Jiangsu Province specialized and special new enterprise", "Jiangsu Province private technology enterprise", "four-star cloud enterprise", "Changzhou Internet benchmark Factory". Furthermore, the company is also certified as "Changzhou Intelligent Manufacturing Demonstration Workshop", "Integrity Operation Demonstration Unit", "Changzhou New Energy Servo Stator Core Engineering Technology R&D Center", "Member of tooling & Mold Industry Association".

Yuma's Demonstrated

Manufacturing Capacity

in Fuel Vehicle Electric Motors

Our Supplier

Let's start getting a quote!

Quickly experience the five-star manufacturing service we bring to you!

Get A Quote Now